HOME > Japan SPOTLIGHT > Article

Efforts to Decommission the TEPCO Fukushima Daiichi Nuclear Power Station

By Nuclear Accident Response Office, Agency for Natural Resources & Energy, Ministry of Economy, Trade & Industry

Introduction

More than seven years have passed since the accident at the TEPCO Fukushima Daiichi Nuclear Power Station. Having emerged from the initial post-accident emergency response, efforts to decommission the power station and manage contaminated water are moving forward safely and steadily based on the Mid-to-Long-Term Roadmap Towards the Decommissioning of TEPCO Fukushima Daiichi Nuclear Power Station. This paper presents an overview of the schedule for decommissioning the power station, including a description of measures taken to date since the accident, their effect, and future efforts.

Schedule for Decommissioning the Fukushima Daiichi Nuclear Power Station

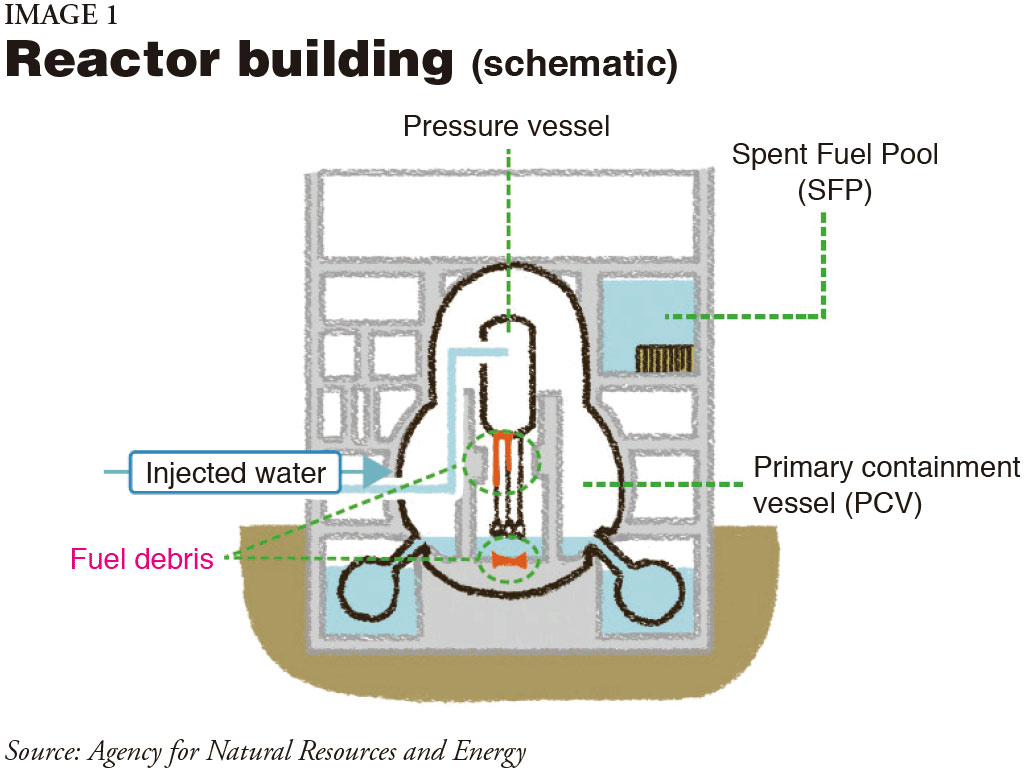

The Japanese government drew up its first Mid-and-Long-Term Roadmap for decommissioning the Fukushima Daiichi Nuclear Power Station in December 2011. As a result of the accident, the meltdown of fuel in the reactor pressure vessels (RPVs) at the power station was accompanied by the generation of hydrogen, which led to hydrogen explosions. Currently, a solidified mixture of melted fuel and surrounding structural material ("fuel debris") remains in the primary containment vessels (PCVs) at Units 1–3, and there is a need to move forward with the processing of radioactive waste and contaminated water.

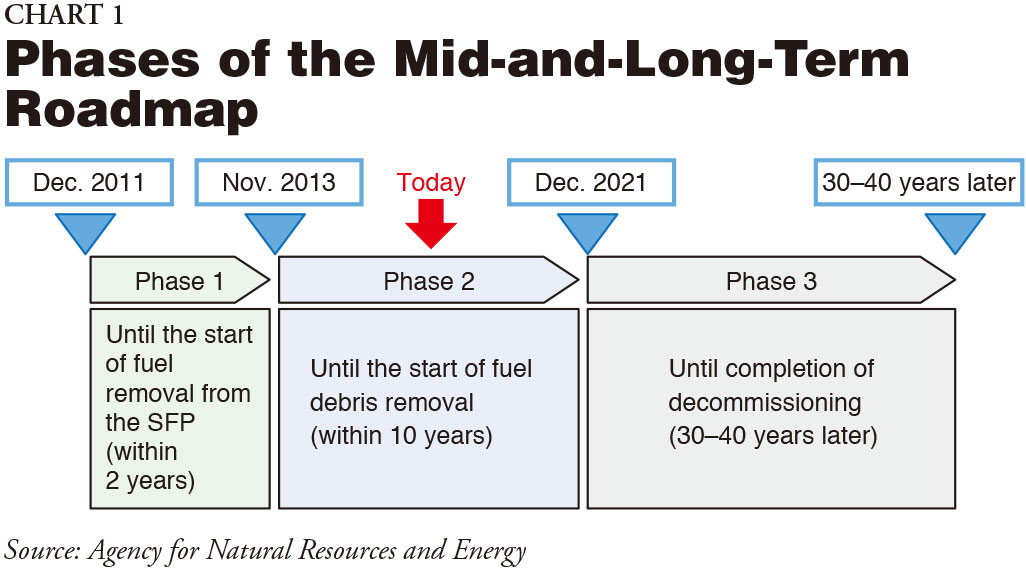

The Mid-and-Long-Term Roadmap lays out a target schedule for each step in the decommissioning work. It is divided into three phases; we are currently in Phase 2.

We would like now to explain the difficultly of decommissioning work at the Fukushima Daiichi Nuclear Power Station. High concentrations of radioactive material within the reactor buildings make it difficult for people to enter to work and difficult to accurately ascertain the details about conditions inside. Undertaken in this environment, the decommissioning of the power station is unprecedented anywhere in the world for its difficulty and, relative to ordinary construction projects for which conditions can be fully ascertained, can be described as a project with inherent uncertainties.

Even amid such uncertainty, however, there is a need to move forward safely and surely in a way that enables coping with unlikely events, proceeding carefully in order to minimize the burden placed on those working on site.

The Mid-and-Long-Term Roadmap has been revised from time to time to optimize it for changing conditions by reflecting new understandings of the conditions in the field as well as the latest knowledge and the results of research and development, with the fourth revision undertaken in September 2017 (Chart 1).

Current Conditions

Each measure will be addressed in turn in the next section, while this section describes the overall situation today at the Fukushima Daiichi Nuclear Power Station.

��Condition of the Fuel

The melted-down fuel debris at Units 1–3 is being kept stable, and the temperature inside the reactors kept low, through a continuous injection of water. Decay heat from the fuel in the Spent Fuel Pool (SFP) has decreased significantly with the passage of more than seven years since the accident. In fact, when the water temperature was checked after cooling of the pool was suspended for one month under severe midsummer conditions, the water temperature was confirmed to remain below the limit (65��C) due to natural heat radiation (Image 1).

Given these stable conditions, the likelihood of another accident is extremely low. Nevertheless, steps are being taken to prepare for the unlikely, including facilities to suppress recriticality and measures to address and train for earthquakes and tsunami.

��Condition of the Site and the Surrounding Area

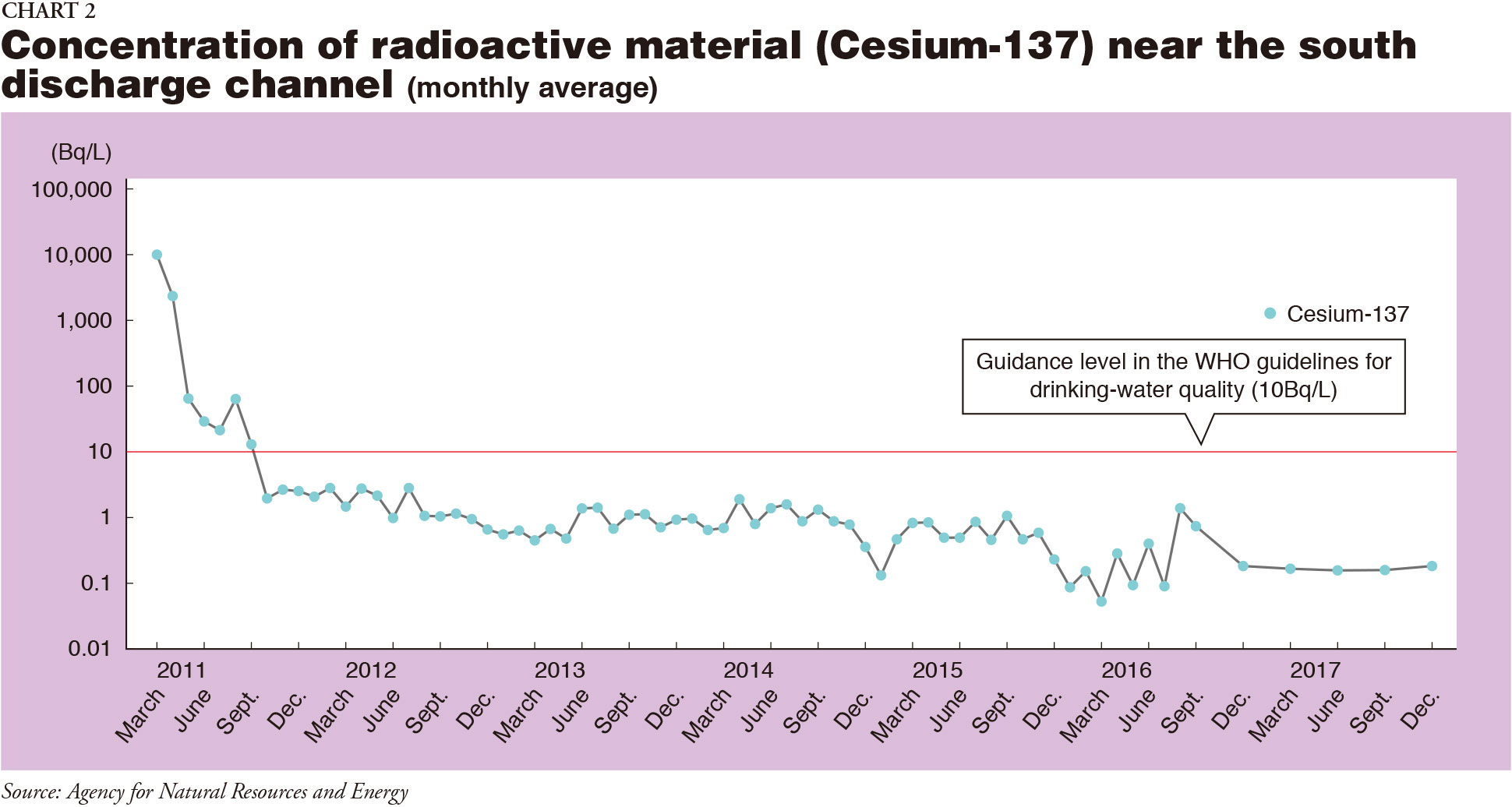

Monitoring posts and dust monitors installed around the perimeter of the power station site keep watch around the clock, and conditions remain stable. The concentration of radioactive material in the seawater in the sea surrounding the power station (outside the harbor), for example, is low enough to ensure public safety, even compared to global water quality standards for drinking water, and an assessment by an international organization has concluded that the marine environment is stable (Chart 2).

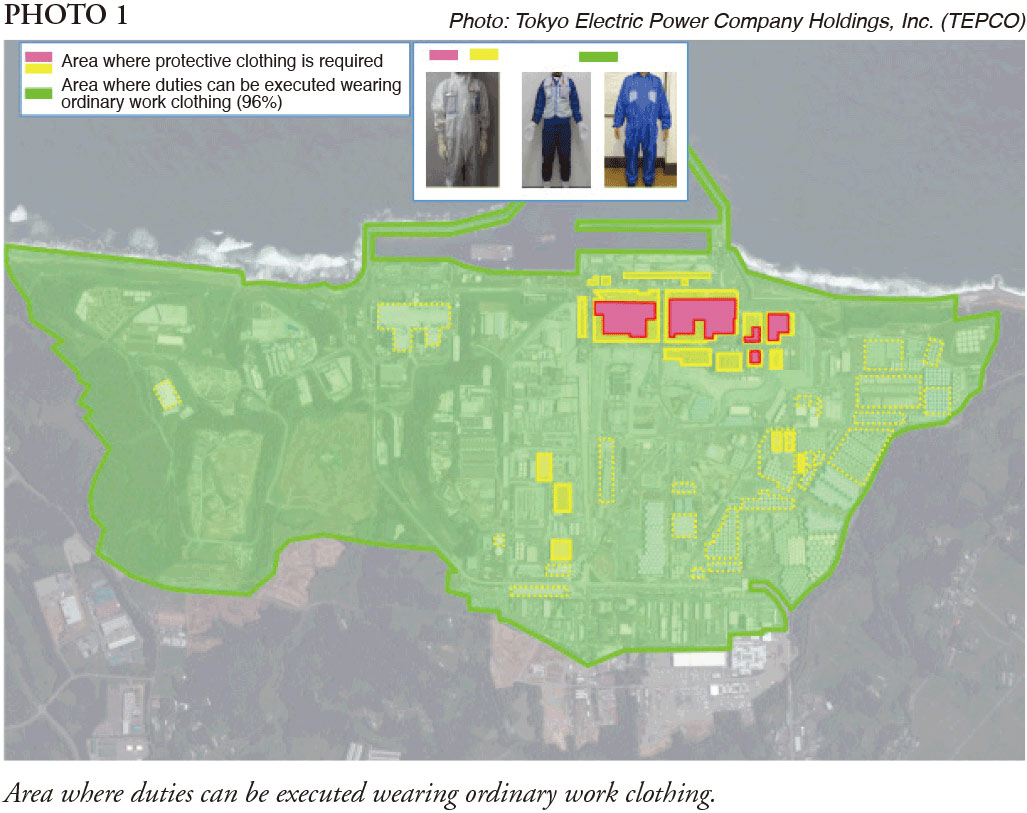

The working environment has also greatly improved. Although protective clothing was required throughout almost the entire area immediately after the accident, measures to reduce radiation doses from the natural environment through decontamination and facing work have made it possible for workers to now carry out their duties in ordinary work clothes at around 96% of the site. In addition, measures have been implemented to bolster medical readiness in time of emergency such as stationing emergency physicians on site around the clock and installing a heliport to reduce the time required for transport. A large rest house has also been constructed that incorporates a restaurant, shops, and shower rooms, can accommodate 1,200 people at a time, and serves hot, delicious, locally-prepared meals.

Efforts will continue to be made to provide a safe and improved working environment in order to move steadily forward with decommissioning over the long term (Photo 1) .

Progress of Each Measure & Future Efforts

(1) Efforts Leading to Fuel Debris Retrieval

(i) A Fourth Revision of the Mid-and-Long-Term Roadmap

As described above, the Mid-and-Long-Term Roadmap underwent a fourth revision in September 2017. One of the key points in this revision was the determination of the policy on fuel debris retrieval. Safely completing this retrieval is a major target on the schedule leading to decommissioning. The determination of the policy on the retrieval in the revision in 2017 came about as the result of various research and analysis that revealed previously unverifiable details about the situation inside of Units 1–3.

(ii) Investigation Towards Fuel Debris Retrieval

Investigation environments that people could not enter directly required both existing techniques and bringing together wisdom from Japan and overseas to conduct computer analyses as well as research utilizing a variety of cutting-edge technologies.

1 Development of Robots Adapted to Conditions Inside the Reactors

Conditions inside the reactors are severe, with high radioactivity and almost no light. In addition, approach routes are difficult to navigate, being narrow with many obstacles and other unexpected impediments.

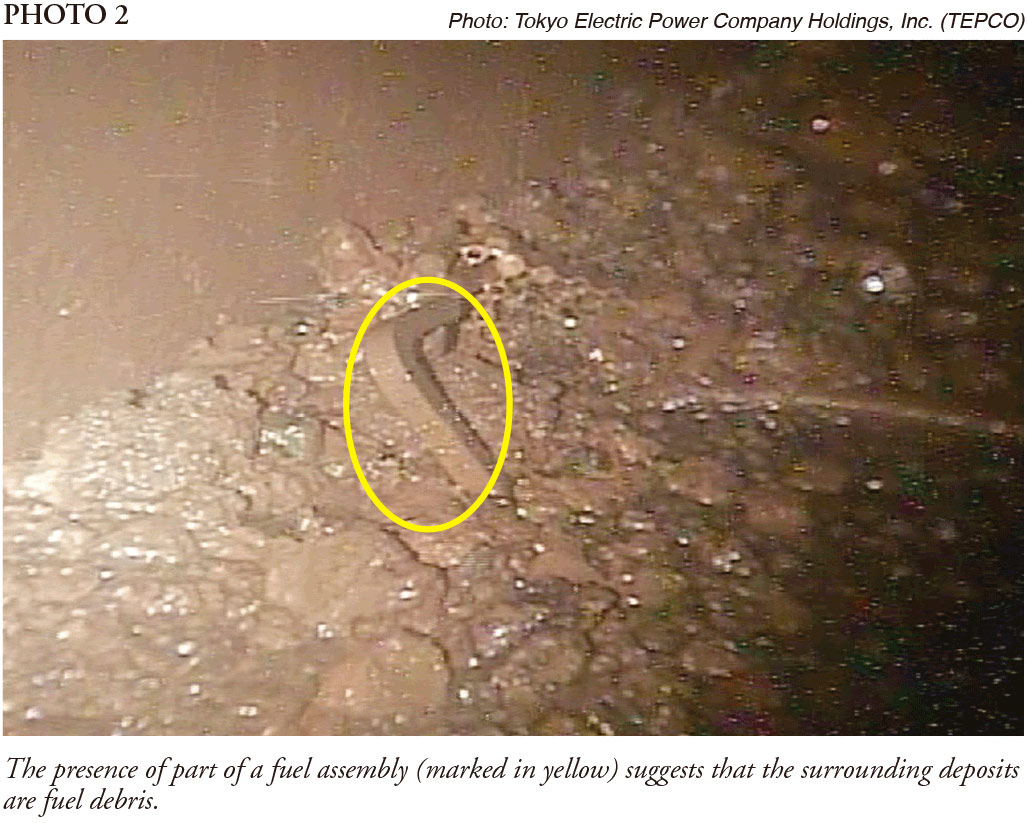

Investigations, then, were conducted using robots in an effort to gather a variety of data in order to grasp conditions insider the reactor building that could not be observed directly by people, such as radiation levels and the state of damage. Previously, a number of robots optimized to various conditions were developed for remote-control investigations, including robots that changed shape in accordance with their route or that could swim under water. The surveys made it possible to image conditions inside the reactors and to confirm the presence of deposits thought to be fuel debris. It was also possible to confirm whether there was space to work toward retrieval of the fuel debris (Photo 2).

2 Investigations Using Cosmic-ray Muons

In investigating the inside of the PCVs, muons — a kind of cosmic ray that rains down from space — were used to visualize the situation inside the reactors.

Muons pass through nearly all kinds of material but are unable to pass through high-density material such as fuel that has melted and solidified. Taking advantage of this characteristic, it is possible to analyze the volume of material in substances along the path that is traced by flying particles and, seeing inside the reactor as if looking at an x-ray, to determine whether or not the fuel is in the reactor core.

The findings revealed that almost no fuel remained in the reactor core of RPV at Unit 1, and the possibility that some fuel debris remained in the bottom of the RPVs at Units 2 and 3.

(iii) Determination on the Policy on Fuel Debris Retrieval

The fuel debris is currently being cooled and kept stable. Nevertheless, from a mid-to-long-term risk management perspective, it is impossible to remove all uncertainty or uneasiness so there is a need to retrieve the fuel debris as soon as possible and transport it to a safe place for stable storage.

As previously described, investigations to date using a variety of methods have revealed important information about the inside of the reactors, including information on the distribution of fuel debris, information needed to confirm access routes to fuel debris, and information to help evaluate work safety.

As a result, the following retrieval policies have been determined in the revision in 2017:

• A step-by-step approach should be adopted, beginning with small-scale tasks and then expanding gradually to larger-scale tasks while confirming the situation and flexibly reviewing methods based on the information thereby obtained.

• With regard to retrieval policies, given the technological difficulty of the "full submersion method" of completely filling the reactor containment vessel with water, emphasis should be placed on retrieval of fuel debris from the vessel using "partial submersion methods".

• Primary emphasis should be placed on retrieving fuel debris at the bottom of the containment vessel using a side-access method.

Given the above policies, deliberations leading to debris retrieval are now underway, with further interior investigations and technological developments moving forward toward the retrieval of fuel debris beginning in 2021.

In addition, in order to ascertain the feasibility of the work, TEPCO, the principal for carrying out the decommissioning, will move forward in deliberating engineering aspects to ensure a smooth transition to the actual work of retrieval.

(2) Management of Contaminated Water

In the reactor buildings, the reactors are kept stable at low temperature by cooling them with water, but this water mixes with groundwater flowing into the buildings, generating new contaminated water every day. Multilayered prevention measures, therefore, are being taken in line with the three basic principles of (i) isolating water from sources of contamination, (ii) preventing leakage of contaminated water, and (iii) removing sources of contamination.

(i) Isolation Measures

Measures to isolate water from sources of contamination are aimed at reducing the volume of contaminated water generated, with a combination of various measures taken to constrain the flow of groundwater into the buildings.

Specific measures taken include a groundwater bypass that draws groundwater from the mountain side of the buildings and discharges it into the ocean, sub-drains and groundwater bypasses nearer the buildings that draw groundwater and discharge it into the ocean after purification, a land-side impermeable wall made of frozen soil and groundwater, and wide-area paving of the site to prevent rainwater from seeping into the soil. These measures have greatly reduced the volume of contaminated water generated. (Before measures: approx. 540m3/day; FY 2017 average: approx. 220m3/day)

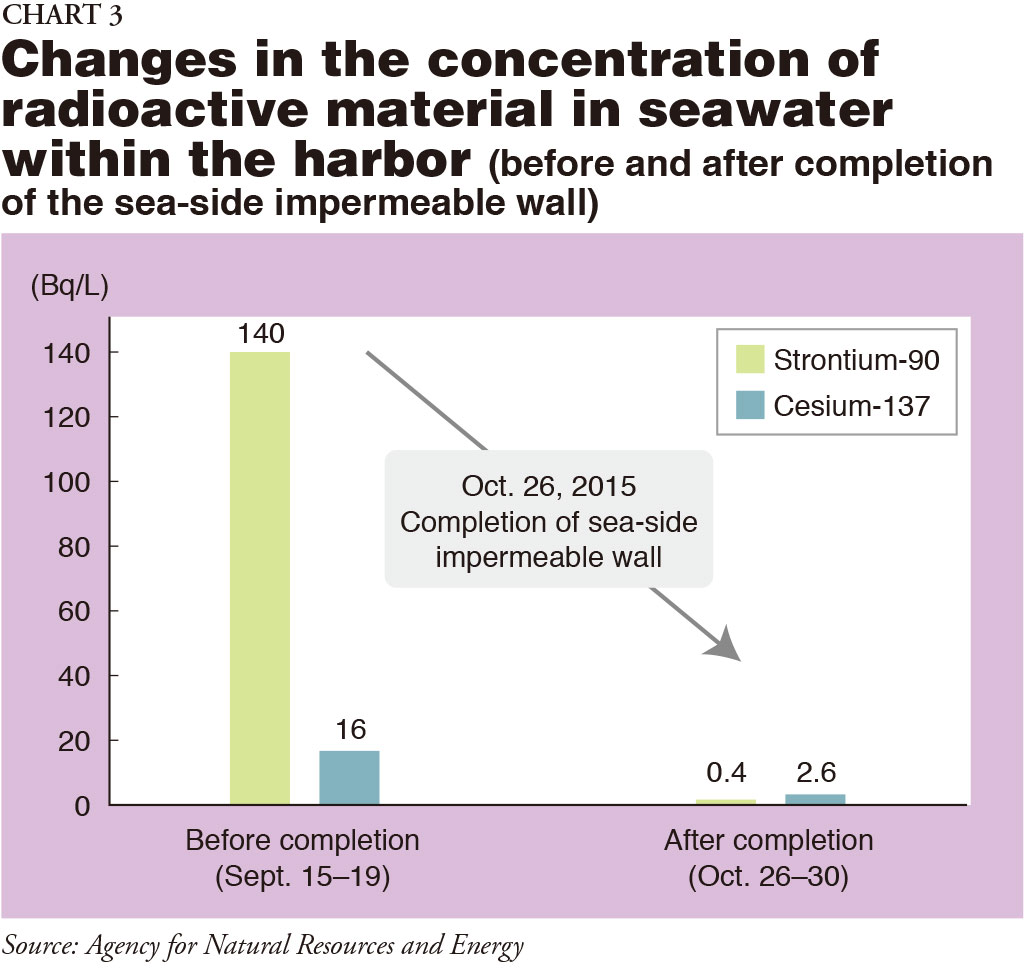

(ii) Measures to Prevent Leakage

Measures to prevent leakage of contaminated water are aimed at reducing the risk of radioactive material outflowing to the sea. In October 2015, construction was completed on the installation of a 30-meter-deep, 780-meter-long wall of steel pilings on the ocean side of the buildings (the sea-side impermeable wall). This has greatly reduced the volume of radioactive material outflowing into the harbor and the water quality in the harbor is confirmed to be gradually improving. Furthermore, in addition to proceeding with new installations of high-reliability welded storage tanks, and the replacement of flange-type storage tanks made of bolted steel plates with such welded tanks, preventative measures are also being taken to prepare for any unexpected leakage such as double-diking in the areas surrounding the tanks and installing waterproof seals on the lateral flanges, as well as multiple patrols each day (Chart 3).

(iii) Removal Measures

Measures to remove sources of contamination include purifying contaminated water using multiple purification facilities including multi-nuclide removal equipment (ALPS: Advanced Liquid Processing System) and then storing it in tanks. In particular, processing of the highly contaminated water that was problematic after the accident concluded in May 2015; today, it is purified water that is being stored in tanks. Highly contaminated water also collected in the underground tunnel on the sea-side of the reactor buildings (seawater piping trench), posing a large risk in the event of unexpected leakage. This contaminated water, therefore, was pumped out and the trench interior filled in and blocked off, with the removal of contaminated water and filling in of the trench completed by December 2015, which greatly reduced risk.

Due to these multilayered preventative efforts, great progress has been made in managing contaminated water. In order to bring final resolution to the issue of contaminated water, however, continued efforts are being made for subsequent measures through deliberation by a committee of experts.

(3) Removal of Fuel from the SFP

The removal of fuel on the way to decommissioning means the removal of an enormous risk; transporting the fuel from the damaged buildings to a sound building will enable storing and managing it in a safer place.

(i) Completion of Fuel Removal from the SFP at Unit 4

Removal of fuel from the SFP at Unit 4, considered among the highest priority issues at hand, was completed in December 2014. All of the 1,535 fuel assemblies were transferred to a common SFP.

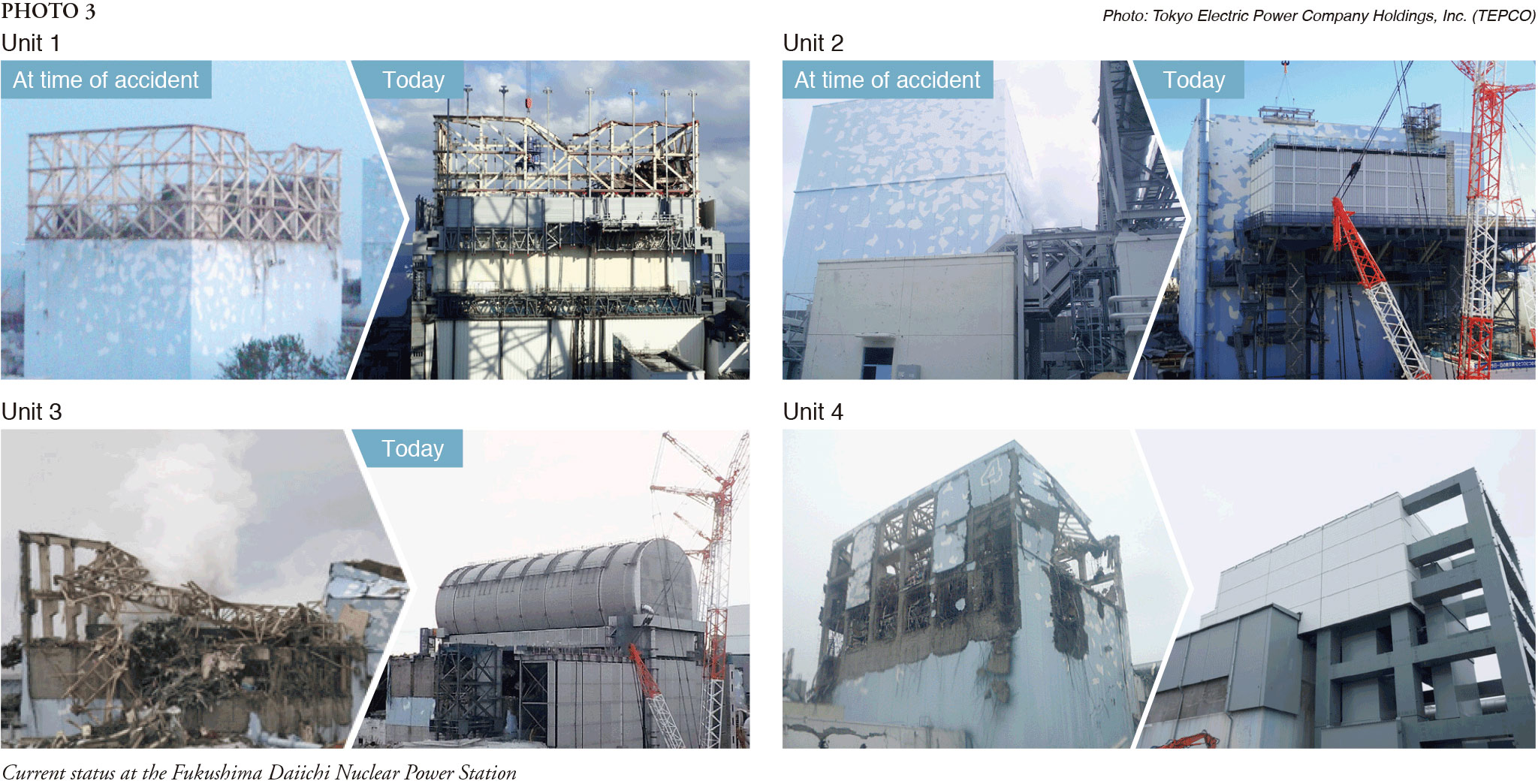

(ii) Fuel Removal from the SFPs at Units 1–3

At Unit 1, removal of the reactor building cover has been completed, and windbreak fencing and work platforms installed. Work is underway to remove rubble from the north side of the operating floor. At Unit 2, which avoided explosion, an opening has been installed on the west side of the building and surveys of the operating floor are being conducted. Fuel removal at Units 1 and 2 is scheduled to begin in FY 2023. At Unit 3, installation of a cover in preparation for fuel removal has been completed and fuel removal is schedule to begin around mid-FY 2018.

Furthermore, to ensure that radioactive material does not scatter during these operations, thorough protective measures such as the spraying of anti-scattering agents are being undertaken and the concentration of radioactive materials at work sites is being strictly monitored (Photo 3).

(4) Waste Management

The safe storage of radioactive waste generated in the process of decommissioning is of primary importance. The solid radioactive waste that is generated will be categorized by surface dose rate and stored appropriately at the solid waste storage building or at outdoor facilities. Efforts are also being made to secure sufficient storage space based on estimates of the volume that will be generated going forward.

Solid radioactive waste from the Fukushima Daiichi Nuclear Power Station where the accident occurred has characteristics that differ from the radioactive waste normally generated at a nuclear power station, so research and development leading to processing and disposal is underway while ascertaining these properties (Photo 4 & Image 2).

Conclusion

Above, we have described the decommissioning schedule for the Fukushima Daiichi Nuclear Power Station and the progress made to date. The working environment at the power station remains difficult, however, because the task is unprecedented and there are many places on site where doses are high. Going forward, therefore, it will be necessary to review matters flexibly to address new information, possibly including additional safely measures or altering the nature of the work to be done.

In addition, there is a need to broadly communicate the procedures for decommissioning as a whole and its individual steps both to local residents and to those concerned in Japan and overseas.

For the sake of Fukushima reconstruction, the work of decommissioning must be accomplished no matter what it takes. Work will continue over the mid to long term. Bringing together the capabilities of the world as well as Japan and making safety the highest priority, the national government will stand at the fore and do everything in its power to move the project forward.

Japan SPOTLIGHT September/October 2018 Issue (Published on September 10, 2018)

(2018/09/25)

Nuclear Accident Response Office, Agency for Natural Resources & Energy, Ministry of Economy, Trade & Industry